1. High capability of pressure for general water flow with 3~7 filter cartridge.

2. Swing-bolt type contributes to tightly closure without tool.

3. Well O-ring groove design improves sealing and prevent loosening

4. One well design pedestal is available with both DOE and SOE cartridge specification.

5. Opening angle of 105 degree for easy and space-saving bag filter change-outs.

Water treatment

RO protection and pre-filtration process

Seawater

Groundwater

Sludge treatment

Food & Beverage Industry

Wine & Beer

Food industry

Chemicals & Biotechnology

Pharmaceutical & Cosmetic

Electroplating Industry

Electronic Industry

Semiconductor

Refinery & Production Filtration

Automotive

Mining, Oil & Gas

Cooling tower

| TH | 7 | 2 | 4 | F | 2 | 10K | E | EA |

| Model | No. of Rounds | Length | Material | Adapters | Connection Size | Connection Type | O-ring | Outside & Inside Finishes |

TH |

3 4 5 6 7 |

1-10" 2-20" 3-30" 4-40" |

4-304 6-316 6L-316L

|

F-DOE 5-222 7-226 |

21-1/2" 43-3/4" 1-1" 121-1-1/2" 2-2" 221-2-1/2" 3-3" 4-4"

|

150P-ANSI 10K-JIS PN10-DIN C-Clamp PF-PT/BSPT/Rc

|

E-EPDM N-NBR V-VITON S-SILICONE TS-TEFLON+SILICONE |

A-ACID Pickling E-Electropolishing P-Polishing S-Sand Blasting |

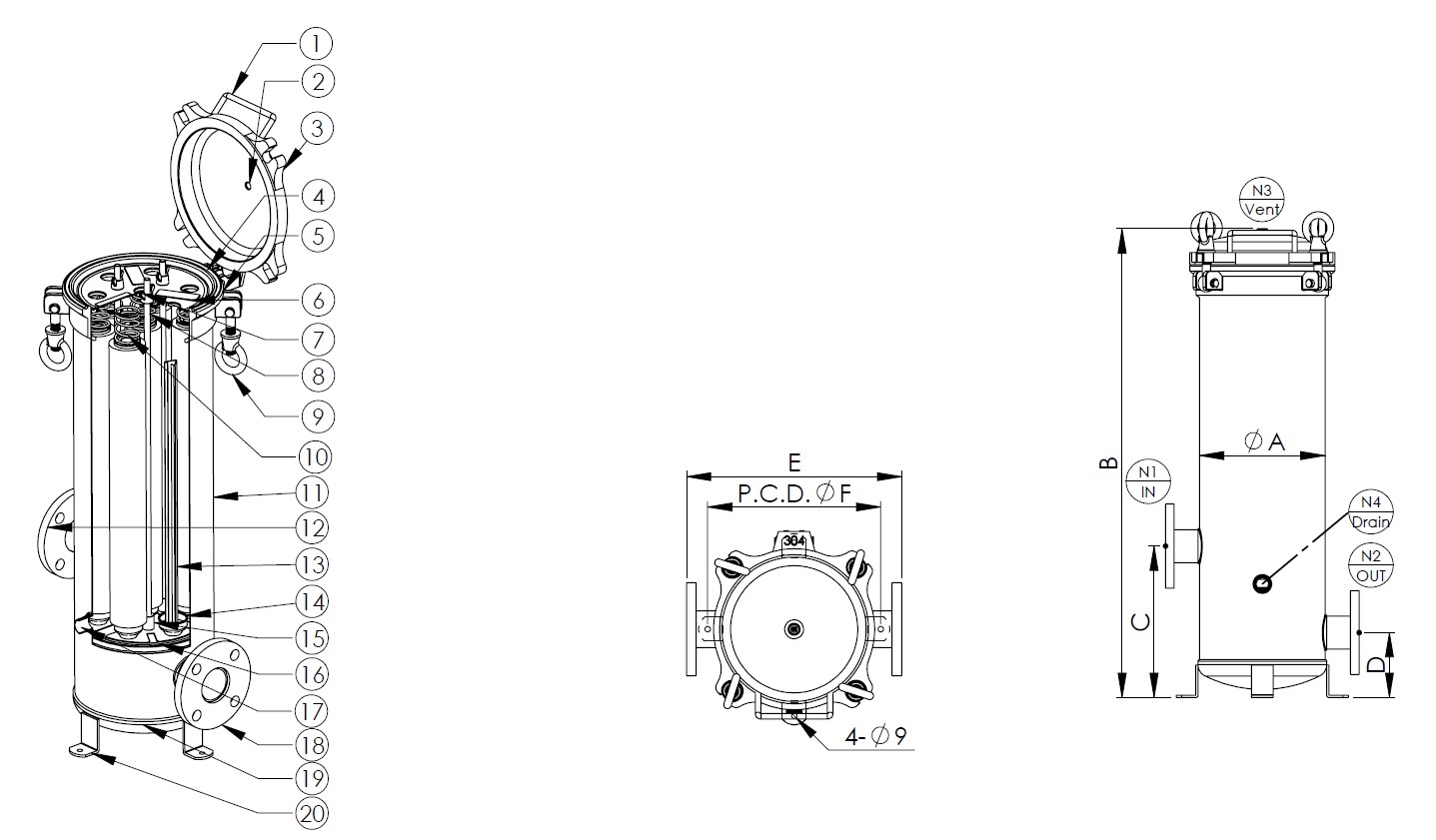

1. Handle

2. Vent

3. Top cover

4. O-ring

5. Shell flange

6. Pressure plate

7. Nut

8. Center post

9. Eye bolt

10. Springs

11. Shell

12. Inlet

13. Cartridge post

14. Pedestal

15. Nut

16. Cartridge support plate

17. Drain

18. Outlet

19. Bottom cover

20. Support leg

| Model | Length | N1/N2 | N3 | N4 | A m/m | B m/m | C m/m | D m/m | E m/m | F (PCD) m/m | M³/Hr | GPM |

| TH3~4 | 10" | 1/2"~3" | 1/4" | 3/4" | Ø180 | 641 | 280 | 120 | 300 | Ø236 | 3~4 | 13~18 |

| TH3~4 | 20" | 1/2"~3" | 1/4" | 3/4" | Ø180 | 896 | 280 | 120 | 300 | Ø236 | 6~8 | 26~35 |

| TH3~4 | 30" | 1/2"~3" | 1/4" | 3/4" | Ø180 | 1151 | 280 | 120 | 300 | Ø236 | 9~12 | 39~53 |

| TH5~7 | 10" | 1/2"~3" | 1/4" | 3/4" | Ø232 | 605 | 280 | 120 | 358 | Ø288 | 5~7 | 22~31 |

| TH5~7 | 20" | 1/2"~3" | 1/4" | 3/4" | Ø232 | 860 | 280 | 120 | 358 | Ø288 | 10~14 | 44~62 |

| TH5~7 | 30" | 1/2"~3" | 1/4" | 3/4" | Ø232 | 1115 | 280 | 120 | 358 | Ø288 | 15~21 | 66~93 |

| TH5~7 | 40" | 1/2"~3" | 1/4" | 3/4" | Ø232 | 1370 | 280 | 120 | 358 | Ø288 | 20~28 | 88~124 |