1. Large filter housing available with 8~220 filter cartridge.

2. Swing-bolt type contributes to tightly closure without tool.

3. Well O-ring groove design improves sealing and prevents loosening.

4. One well design pedestal is available with both DOE and SOE cartridge specification.

5. Flip type cover is available for 8~12 cartridges.

6. Davit type cover is available for up to 13 cartridges in consideration of safety.

Water treatment

RO protection and pre-filtration process

Seawater

Groundwater

Sludge treatment

Food & Beverage Industry

Wine & Beer

Food industry

Chemicals & Biotechnology

Pharmaceutical & Cosmetic

Electroplating Industry

Electronic Industry

Semiconductor

Refinery & Production Filtration

Automotive

Mining, Oil & Gas

Cooling tower

| TM | 20 | 3 | 4 | F | 3 | 10K | E | EA |

| Model | No. of Rounds | Length | Material | Adapters | Connection Size | Connection Type | O-ring | Outside & Inside Finishes |

TM |

8-220 |

3-30" 4-40" |

4-304 6-316 6L-316L |

F-DOE 5-222 7-226 |

2-2'' 3-3'' 4-4'' 5-5'' 6-6'' 8-8'' 10-10'' 12-12'' |

150P-ANSI 10K-JIS PN10-DIN C-CLAMP |

E-EPDM N-NBR V-VITON S-SILICONE TS-TEFLON+SILICONE |

A- ACID Pickling E- Electropolishing P- Polishing S- Sand Blasting |

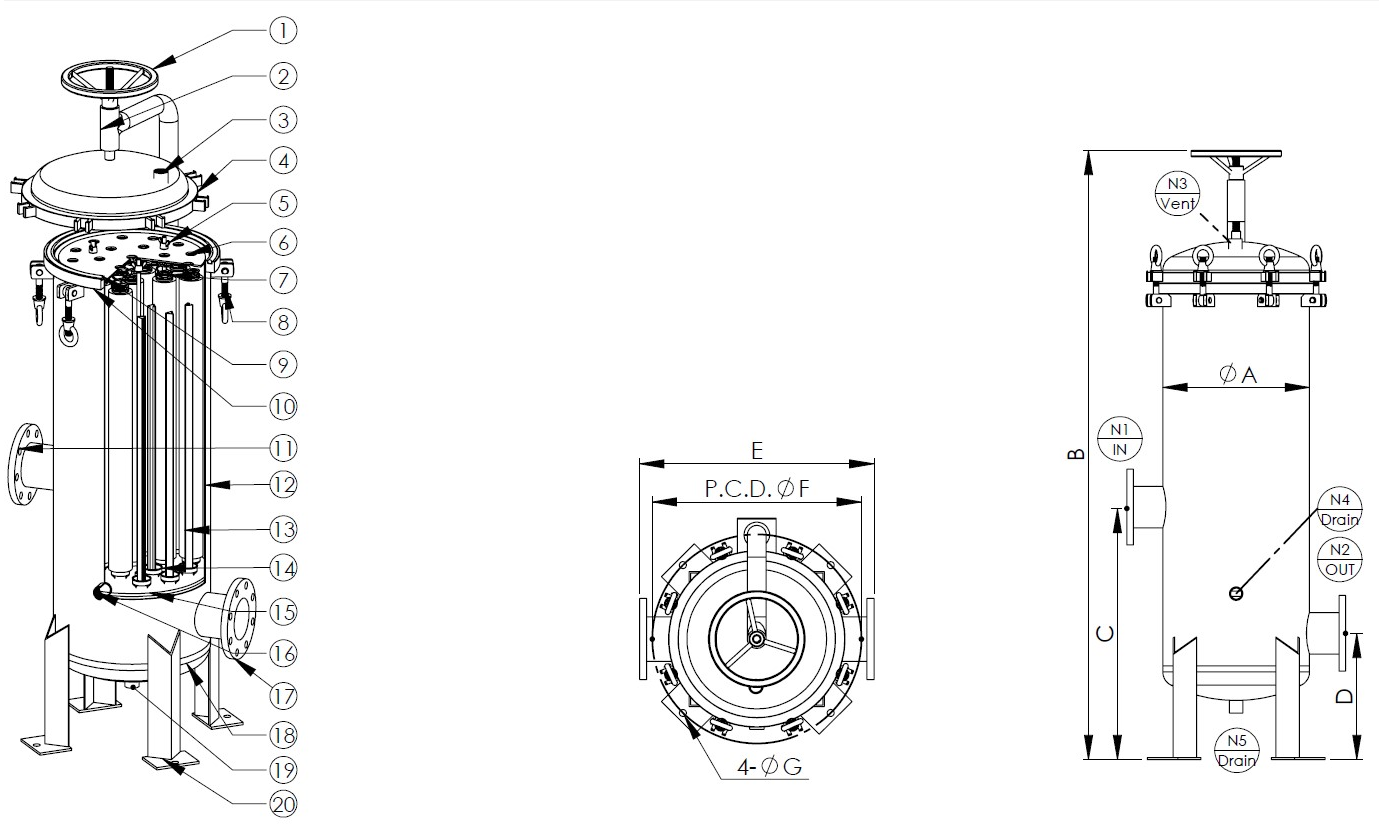

1. Turntable

2. Davit

3. Vent

4. Top cover flange

5. Nut

6. Pressure plate

7. Springs

8. Eye bolt

9. O-ring

10. Shell flange

11. Inlet

12. Shell

13. Cartridge Post

14. Pedestal

15. Cartridge support plate

16. Drain

17. Outlet

18. Bottom cover

19. Drain

20. Support Leg

| Model | Length | N1/N2 | N4/N5 | A m/m | B m/m | C m/m | D m/m | E m/m | F (PCD) m/m | G m/m | M³/Hr | GPM |

| TM8~12 | 30" | 2"~4" | 1" | Ø306 | 1638 | 700 | 350 | 506 | Ø416 | Ø14 | 24~36 | 106~159 |

| TM8~12 | 40" | 2"~4" | 1" | Ø306 | 1888 | 700 | 350 | 506 | Ø416 | Ø14 | 32~48 | 141~211 |

| TM13~20 | 30" | 2"~4" | 1" | Ø406 | 1727 | 700 | 350 | 606 | Ø516 | Ø14 | 39~60 | 172~264 |

| TM13~20 | 40" | 2"~4" | 1" | Ø406 | 1977 | 700 | 350 | 606 | Ø516 | Ø14 | 52~80 | 229~352 |

| TM21~35 | 30" | 3"~4" | 1" | Ø508 | 1746 | 700 | 350 | 708 | Ø618 | Ø14 | 63~105 | 277~462 |

| TM21~35 | 40" | 3"~4" | 1" | Ø508 | 1996 | 700 | 350 | 708 | Ø618 | Ø14 | 84~140 | 370~616 |

| TM36~40 | 30" | 3"~4" | 1" | Ø560 | 1778 | 700 | 350 | 760 | Ø704 | Ø18 | 108~120 | 476~528 |

| TM36~40 | 40" | 3"~4" | 1" | Ø560 | 2028 | 700 | 350 | 760 | Ø704 | Ø18 | 144~160 | 634~704 |

| TM41~52 | 30" | 4"~6" | 1" | Ø600 | 1864 | 800 | 400 | 800 | Ø744 | Ø18 | 123~156 | 542~687 |

| TM41~52 | 40" | 4"~6" | 1" | Ø600 | 2441 | 800 | 400 | 800 | Ø744 | Ø18 | 164~208 | 722~916 |

| TM53~57 | 30" | 4"~6" | 1" | Ø650 | 1925 | 850 | 450 | 850 | Ø794 | Ø18 | 159~171 | 700~753 |

| TM53~57 | 40" | 4"~6" | 1" | Ø650 | 2175 | 850 | 450 | 850 | Ø794 | Ø18 | 212~228 | 933~1004 |

| TM58~82 | 30" | 4"~6" | 1-1/2" | Ø762 | 2063 | 950 | 500 | 962 | Ø962 | Ø19 | 174~246 | 766~1083 |

| TM58~82 | 40" | 4"~6" | 1-1/2" | Ø762 | 2313 | 950 | 500 | 962 | Ø962 | Ø19 | 232~328 | 1021~1444 |

| TM83~117 | 30" | 6"~8" | 2" | Ø900 | 2225 | 1000 | 550 | 1100 | Ø1100 | Ø19 | 249~351 | 1096~1545 |

| TM83~117 | 40" | 6"~8" | 2" | Ø900 | 2475 | 1000 | 550 | 1100 | Ø1100 | Ø19 | 332~468 | 1462~2061 |

| TM118~146 | 30" | 6"~8" | 2" | Ø1000 | 2299 | 1100 | 600 | 1200 | Ø910 | Ø22 | 354~438 | 1559~1928 |

| TM118~146 | 40" | 6"~8" | 2" | Ø1000 | 2549 | 1100 | 600 | 1200 | Ø910 | Ø22 | 472~584 | 2078~2571 |

| TM147~185 | 30" | 10"~12" | 2" | Ø1100 | 2442 | 1250 | 650 | 1300 | Ø1010 | Ø22 | 441~555 | 1942~2444 |

| TM147~185 | 40" | 10"~12" | 2" | Ø1100 | 2692 | 1250 | 650 | 1300 | Ø1010 | Ø22 | 588~740 | 2589~3258 |

| TM186~220 | 30" | 10"~12" | 2" | Ø1220 | 2465 | 1250 | 650 | 1400 | Ø1130 | Ø22 | 558~660 | 2457~3258 |

| TM186~220 | 40" | 10"~12" | 2" | Ø1220 | 2715 | 1250 | 650 | 1400 | Ø1130 | Ø22 | 744~880 | 3276~3875 |